ANODIZATION

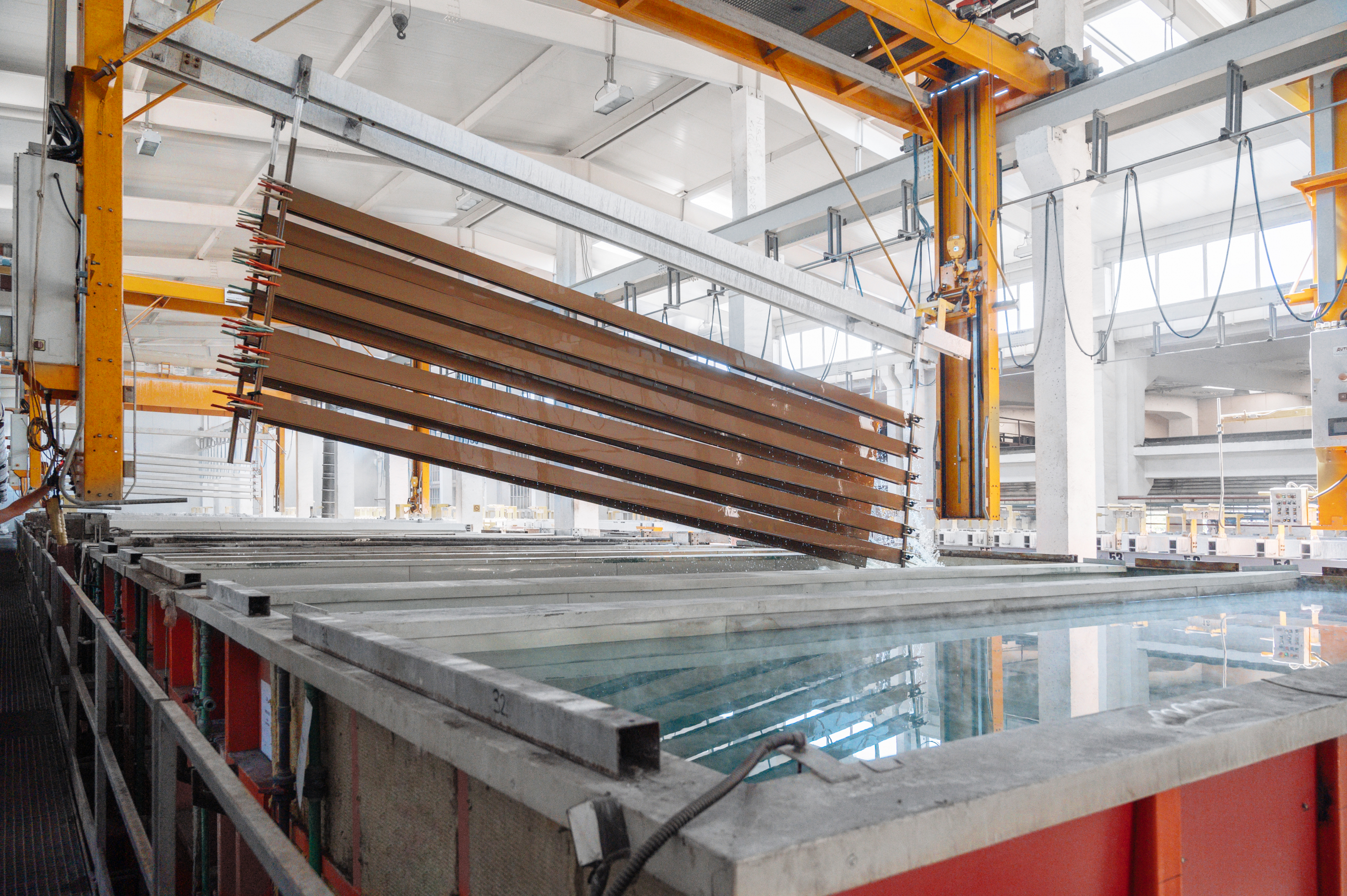

Anodic oxidation of aluminum profiles is done in the plant with a capacity of 150t. The process takes place in 25 different bathrooms.

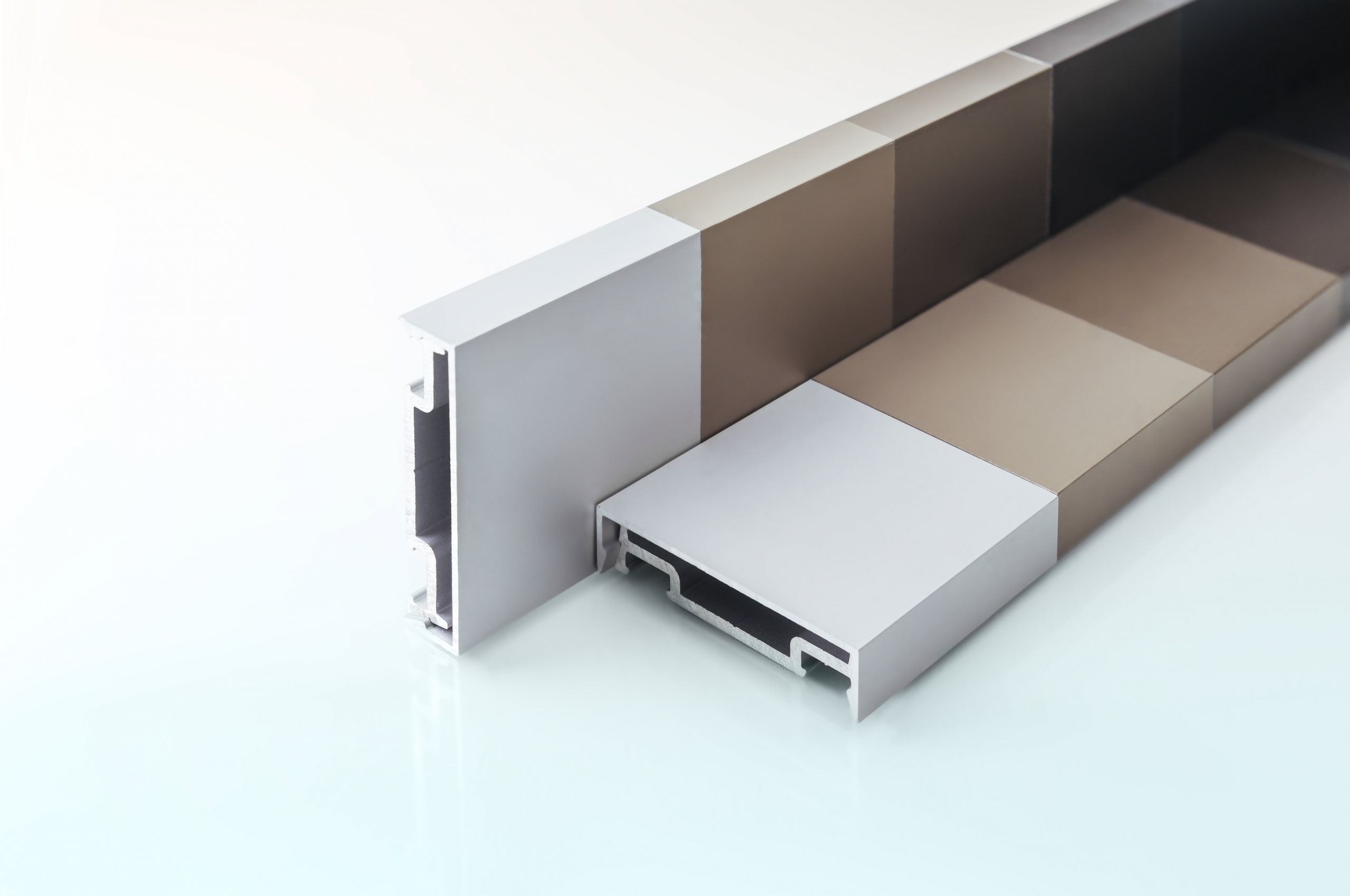

Anodizing and electrochemical colouring is performed according to the own tone card and tone map of the European Association of Anodic Oxidation “EURAS” (which are compatible), starting from the natural color of aluminum, through light bronze, medium bronze, dark bronze to black. Anodizing aluminum profiles of all constructions and lengths up to 7.5 m, and sheet metal with maximum dimensions of 7.5 m x 2.0 m is feasible.

The thickness off oxide layer of anodizing depends on the customer’s requirements and the purpose of the profile itself. The capacity of the plant is 150 tons of aluminum profiles per month, and it is planned not only to meet the requirements of its own production but also to provide services to external customers.

The technological process involves the following stages:

- Mechanical preparation performed by brushing of the profile, whereby a uniform appearance of a significant surface of the profile is obtained.

- Chemical preparations by which degreasing and etching of the aluminum surface is performed to apply a quality layer of aluminum oxide at a later stage. By adding a sanitizing agent to the surface, at the end of this phase a fine silky surface of aluminum is obtained.

The quality of the anodic layer depends on the quality of aluminum, mechanical and chemical preparation, electrolyte concentration, temperature and density of the current.

The fact that the control of these parameters is left not only to the human factor, but also to the computer programming and monitoring is of significance. The software constantly monitors and manages the anodizing process, uniformity of the density of the current, solution concentration, temperature, as well as the thickness of the anodic layer.

The final anodic oxidation products are tested on daily basis in our own laboratory according to QUALANOD standards, under the guidance of the team of technologists with many years of experience that guarantees the quality of the delivered product.

MTC NISSAL DOO

MTC NISSAL DOO

Gandijeva 235/13, 11073 Beograd

Production:

Bulevar Sv. Cara Konstantina bb, 18110 Niš